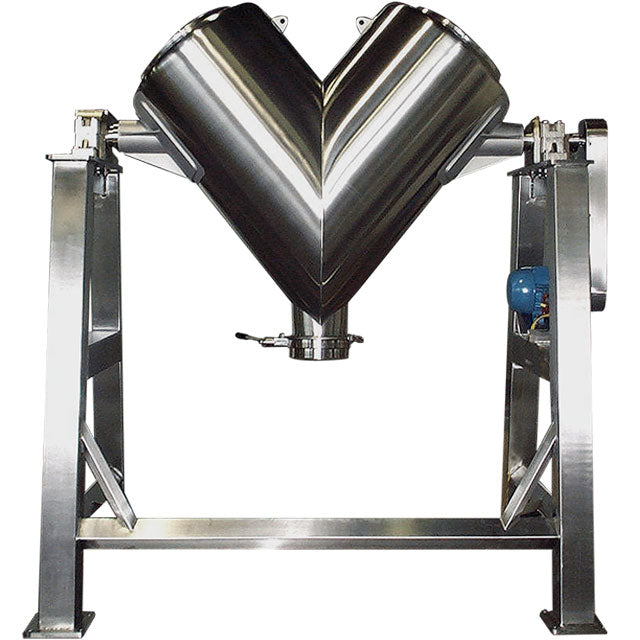

Operations

V-Blending Operations

2 Large Commerical V-Blenders

Advanced pharmaceutical blending techniques

With a Focus on PRECISION and QUALITY combining ingredients to ensure uniformity and potency.

Dynamic control of blending parameters

The pharmaceutical blending process at Health Pharma plays a vital role in delivering safe and effective Products.

Tablet Compression

6 Cutting-edge pharmaceutical tablet presses for compression producing high-quality medications and nutraceuticals.

B-TOOLING & D-TOOLING OPERATION

Efficiency on Machines- Over 3 to 4 million tablet runs per day on a single machine.

Maintenace and Oversight on compression machines performed Daily, Yearly Third-Party Inspection on All Machinery.

ROUND, OVAL or CONVEX SHAPES POSSIBLE for TABLETS

Use of state-of-the-art tablet presses guarantees the production of reliable and effective tablets for all clientele.

Contract Coating

2 Precise pharmaceutical tablet coating techniques to enhance the appearance, taste, and stability of medications.

Using advanced coating equipment, a single or multilayer coating is applied to the tablets.

FILM COAT, CLEAR COAT, ENTERIC COATED, BLENDED COAT ALL POSSIBLE

All guidelines and rules adherence to regulatory standards are followed throughout the process.

Visually appealing and easy-to-administer tablets and nutraceuticals for all customers.

Capsule Compression

2 State-of-the-art pharmaceutical capsule machines

Efficiency of machines- 2 to 4 million capsules per machines per day.

Advanced machines fill and seal capsules with precise dosages.

With stringent quality control measures, all parameters of consistency, capsule weight, integrity, and dissolution properties are tested.

Guarantees the production of reliable and convenient dosages for all customers.